Описание

Massive! Rigid!

Designed and built specifically for heavy cutting

- Main body casting iron adopt Meehanite Iron to ensure its high quality and long machine life.

- Box style designed main body structure with reversed "Y" type big span vertical column to greatly enhance the rigidity and stability of machine itself.

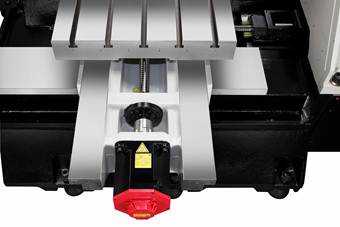

- Three axes adopt box guide way suitable with heavy loading and cutting.

- All structural touching face using manual scraping to reach the highest accuracy, structural rigidity and even loading.

- High accuracy ball screw and three axis of servo motor designed with direct drive and pretention to improve the transmission rigidity and machining accuracy to lower thermal expansion caused thermal deformation.

- The weight of ram on the head of z axis to be uniformly distributed through dual rib equipped with guide screw suitable with speeding move and move even without shaky, keep the most high accuracy.

- Full enclosed splash guard to prevent chip and chip coolant splashing.

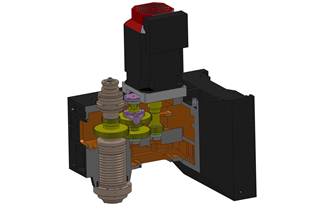

Can match optional gear reducer, with oil coolant greasing to prevent noise to ensure the stability of heavy cutting.

Main spindle standard speed can reach 8000 rpm, with high torque of belt transmissiongreatly lower noise and heat, suitable for high speed heavy cutting

Three axes adopt box guide way suitable with heavy loading and heavy cutting to ensure positional accuracy

Ball screw on three axes adopt direct drive and pretention to highly improve rigidity and machining accuracy

Технические характеристики

| Item | Utit | TMV-1165 | |

|---|---|---|---|

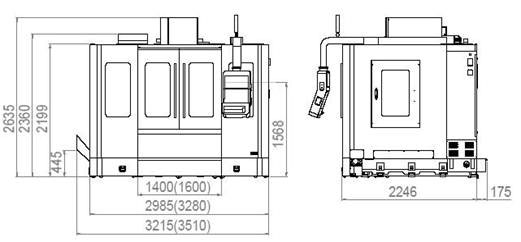

| Machining Travel | X Axis | mm | 1120 |

| Y Axis | mm | 650 | |

| Z Axis | mm | 610 | |

| Spindle Nose to Table | mm | 120〜150 | |

| Working Table to Floor | mm | 850 | |

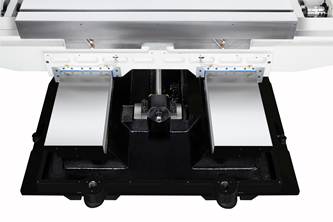

| Working Table | Table Size | mm | 1200 x 650 |

| T slot | mm | 18*5*125 | |

| Max. Table Load | kg | 1000 | |

| Spindle System | Spindle Speed | rpm | 6000/8000 |

| Spindle Drieve | Gear/Belt | ||

| Spindle Taper | BT50/BT40 | ||

| Feed Rate | Rapid Traverse X/Y/Z | M/min | 20/20/20 |

| Cutting Feed Rate | M/min | 1〜4000 | |

| ATC | Tool Magazine Capacity | pcs | 24(Arm Type) |

| Tool Change Time( Tool to Tool) | sec | 1.8(Arm Type) | |

| Max. Tool Dia. | mm | 81/150 (Arm Type) | |

| Max. Tool Length | mm | 300 | |

| Max. Tool Weight | kg | 8(Arm Type) | |

| Motor | Spindle Motor (Cont.15min.Rating) | kw | F 11/15 kw M 7.5/11 kw |

| X/Y/Z Axis Motor | kw | F 2.5/2.5/2.5 kw M 3.5/3.5/3.5 kw |

|

| Coolant Motor | kw | 0.75kw | |

| Other | Coolant Water Cabinet Capacity | L | 350 |

| Power Requirement | KVA | 20 | |

| Air Pressure Requirement | kg/c㎡ | 6 | |

| Machine Dimension (W*L*H) | mm | 3215 x 2910 x 2600 | |

| Machine Weight | kg | 7400 |

Аксессуары

Standard

- Tools, tools kit

- Working lamp

- Pilot lamp

- Coolant gun

- Chip spray

- Cutting coolant system

- Cutting air blast

- Spindle air blast

- Seat flushing system

- Auto lubrication system

- Auto power off

- RS-232

- Heat exchanger

- Spindle oil cooler

- Arm type ATC 24 tools

- Hinged type chip conveyor

- Adjustment pads and bolt

- Full enclosed splash guard

- Machine, Electricity, operation manual

Optional

- 0.001° indexing rotary table

- Coolant through spindle device

- Linear scale

- Hydraulic system

- Oil mist collection device

- Rotary working table ( The 4th axis )

- Safety door

- Oil skimmer

- Auto tool length measurement

- Oil hole holder function

- Work piece measurement system

- Transformer

- Full enclosed splash guard