Описание

- 24 m/min of rapid traverse rates can be achieved with the design of linear ways on X, Y-axis.

- Box ways on Z-axis ensures high stability during cutting.

- The double-wall box type base combined with oversized column design lead to higher rigidity and stability.

The machine comes equipped with a high performance FANUC 0iMD A controller in combination with the use of α type servo motor. The controller has 1G CF memory card and provides AICC function for high speed machining.

Технические характеристики

| Item | Utit | VMC-168DH | VMC-188DH | |

|---|---|---|---|---|

| Travel | X-axis travel | mm | 1600 | 1800 |

| Y- axis travel | mm | 850 | 850 | |

| Z- axis travel | mm | 700 | 700 | |

| Spindle Nose to Table | mm | 150 ~ 850 | 150 ~ 850 | |

| Spindle Center to Column Face | mm | 930 | 930 | |

| Table | Working surface | mm | 1800 x 850 | 1900 x 850 |

| T-slots (width*number*pitch) | mm | 18 * 5 * 125 | 18 * 5 * 150 | |

| Max. table load | kg | 2000 | 2500 | |

| Spindle | Spindle speed | rpm | 6000 | 6000 |

| Transmission | Gear | Gear | ||

| Spindle nose taper | BBT50 | BBT50 | ||

| Feed | Rapid traverse (X,Y,Z-axis) |

M/min | 24 / 24 / 12 | 24 / 24 / 12 |

| Cutting feed rate | M/min | 1 ~ 12 | 1 ~ 12 | |

| Auto Tool Changer | Tool storage capacity | pcs | 24 (32 Opt.) | 24 (32 Opt.) |

| Tool change time (tool to tool) |

sec. | 3.5 | 3.5 | |

| Max. tool diameter / adj. empty tool |

mm | 110 / 210 | 110 / 210 | |

| Max. tool length | mm | 300 | 300 | |

| Max. tool weight | kg | 15 | 15 | |

| Miscellaneous | Coolant tank capacity | L | 330 | 330 |

| Electric power required | KVA | 35 | 35 | |

| Air pressure required | kg/c㎡ | 6 | 6 | |

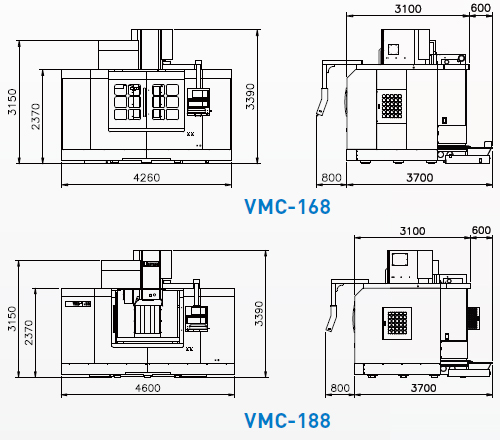

| Machine dimensions (W*L*H) |

mm | 4260 x 4420 x 3390 | 4600 x 4420 x 3375 | |

| Machine weight | kg | 16500 | 17000 |

Аксессуары

Standard

- Fully enclosed splash guard

- Twin chip augers

- Telescopic guards on three axes

- Heat exchanger for electrical cabinet

- Spindle oil cooler

- Cutting air blast device(M07 program controlled)

- Coolant system

- Flushing devices at both sides

- Automatic lubrication system

- MPG handwheel

- Air blast through spindle

- Transformer for external power

- Oil fluid separator (specific gravity type)

- Leveling bolts and blocks

- Warning lamp

- Coolant gun and air gun

- Fluorescent lights at both sides

- Auto power off

- RS-232 interface port

- Adjustment tools with tool box

- Accuracy inspection report

- Machine operation and maintenance manual

- Electronic book for FANUC program maintenance and operation manual

Optional

- Flushing devices at both sides (Independent coolant pump optional)

- Coolant device through tool holder

- 24/32 tool magazine

- Lifting type chip conveyor

- Air conditioner for electrical cabinet

- CNC rotary table (4th axis)

- Automatic tool length measuring device

- Automatic workpiece measuring device

- High speed data server

- AICC2 high speed high accuracy control

- Linear scales on three axes

- Oil mist device

- Oil mist collector

- Disk type oil skimmer

- Coolant through spindle and external-mount filtrating coolant tank

- Working step