Описание

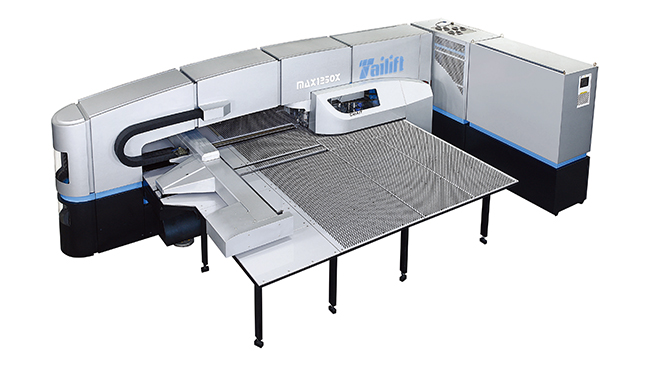

MAX Series for Complex Multi-Tools Auto Index Technology

HIGH PERFORMANCE

FLEXIBILITY IN MULTI-TOOLS

MAX Series Punch Press Machine is the newly developed Multi Index Tools Turret Punch Press equipped with advanced Servo Hydraulic System, introduced by Tailift's professional R&D and production teams who have been dedicated to machineries for decades. Our MAX Series machines provides the fastest, flexible and reliable punch press satisfying your expectation of fast and precise sheet metal works.

Advanced Servo Hydraulic System(ASHS inside)

- Advanced German made Schneider Hydraulic Servo system with pressure valve to precisely control the speed, volume and pressure of oil flow.

- To control the RAM stroke distance on both ends, hence the height and depth of each punch becomes programmable with 0.1mm accuracy.

- Uniquely designed Machine structure ensures less preventive maintenance.

Complex Multi-Tools Auto Index Technology (CMAIT)

- Synchronized dual servo motors for controlling the auto index functions.

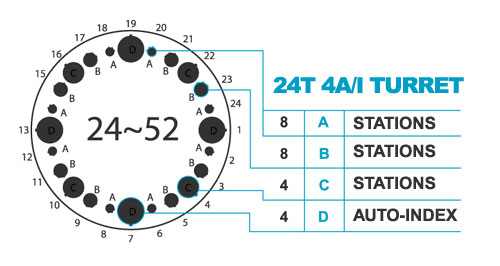

- 4 D Auto Index Stations for Multi Tools, either 3 B or 8 A.

- Capable of indexing each individual tool within the 3B and 8A Multi Tool set.

- 24 various size stations including 4 Auto Index stations Multi Tools.

- Therefore, a total of 24 to 52 tools can be employed.

- Capable of running wheel, marking, grooving and forming Tooling.

Технические характеристики

| Item | Unit | MAX1250X |

|---|---|---|

| Punching Capacity | Tom | 20 |

| X Traverse Length | mm | 2490±10 |

| Y Traverse Length | mm | 1250±10 |

| Max Sheet Size | mm | 1250x4980 |

| Max Sheet Thickness | mm | 6.35 |

| Max Sheet Weight | kg | 110 |

| X Axis Traverse Speed | m/min | 80 |

| Y Axis Traverse Speed | m/min | 70 |

| Max Traverse Speed | m/min | 105 |

| Punch Speed at | hist/min | 360 |

| 25mm Between Holes | ||

| Nibbling Speed | hist/min | 600 |

| Tools Type | Thick turret | |

| Max Punching Diameter | mm | 88.9 |

| Number of Tool Stations | 24~52 | |

| Number of Auto Index Stations | 4/(DType) | |

| Turret Rotating Speed | rpm | 40 |

| Auto Index Rotationg Speed | rpm | 50 |

| Ram Stroke Distance | mm | 0~31 |

| Working Tables Size | Brush | |

| Number of Sheet Clamps | 3 | |

| Power Supply | KVA | 25 |

| Air Supply | NL/min | 250 |

| Oil Tank Volume | L | 350 |

| Air Pressure | bar | 5 |

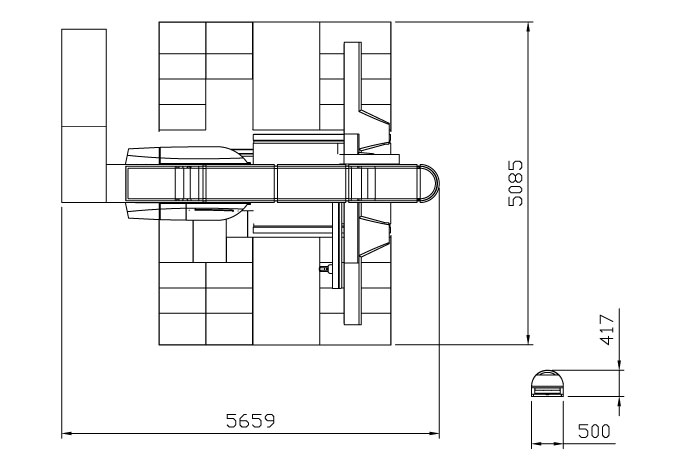

| Machine Size | mm | 5420x5085x2080 |

| Net Weight (apporx) | kg | 14000 |

| Size of Control Cabinet | mm | 1520x700x2080 |

| CNC Controller | FANUC Oi-PD | |

| Number of Controllable Axes | 5+1 | |

| Memory | KB | 256 |

| Serial Interface | USB/PCMCIA/RS232C/RJ45 | |

| Punching Accuracy | mm | ±0.1 |

- Specifications are subjects to change without prior notice.

- Acceleration / deceleration rate of X / Y-axis are dependent on weight of materials.

- Punch speed depends on processing conditions, stroke length, acceleration / deceleration of axes speeds.

Инструментальная турель

| A type 1/2" MAX diameter 12.75mm | 24 ( 8 accept shaped tools ) |

| B type 1-1/4" MAX diameter 31.75mm | 8 ( 8 accept shaped tools ) |

| C type 2" MAX diameter 50.80mm | 4 ( 4 accept shaped tools ) |

| D type 3-1/2" MAX diameter 88.90mm | 4 AUTO. INDEX |

| E type 4-1/2" MAX diameter 114.30mm | 2 ( 2 accept shaped tools ) |

Чертёж